Organoclay As a Potential Eco-friendly Substitute Of Chalk In The Manufacturing Of The PVC Based Electric Cable

DOI:

https://doi.org/10.69717/jaest.v5.i1.120Keywords:

Organoclay, Polyvinyl chloride, Nanocomposite, Mechanical propertiesAbstract

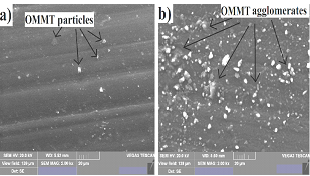

The aim of this work was to study the effects of an organoclay on the properties of a polyvinyl chloride polymer and to compare the obtained results to polyvinyl chloride/chalk counterpart in order to replace the no eco-friendly and no-economic chalk by the cheap and eco-friendly organoclay in the electric cable polyvinyl chloride manufacturing. The obtained nanocomposites were prepared by dry blending followed by extrusion. The x-ray diffraction analysis evidenced an intercalation of the polyvinyl chloride chains between organoclay platelets. The thermal stability (Beilstein test) of the nanocomposite was greatly improved and thermgravimetric analysis (TGA) showed that the formulation containing 1 wt % of organoclay is the more thermally stable up to 240 °C. Differential scanning analysis showed that the glass transition temperature of the nanocomposite is higher than the neat polyvinyl chloride. A rheological analysis revealed that the addition of organoclay had not damaged the processability of the nanocomposite. Scanning electronic microscopy analysis revealed a uniform dispersion of the organoclay particles in the polyvinyl chloride matrix. The PVC based organoclay exhibits properties better than PVC based chalk used in the industry. So, the eco-friendly organoclay can be a good alternative to the expensive and irritating chalk.

Highlights

- 1% organoclay improves PVC strength, ductility, and thermal stability.

- XRD shows intercalation at 1% organoclay, enhancing composite structure.

- DSC confirms higher Tg for 1% organoclay due to chain confinement.

- Organoclay offers better processability and lower energy use than chalk.

- SEM reveals uniform dispersion only at low organoclay loading.

Downloads

References

K. Lewandowski, K Skórczewska, A Brief Review of Poly(Vinyl Chloride) (PVC)Recycling, Polymers, 14 (2022) 3035—3049. https://doi.org/10.3390/polym14153035.

M. Bouakkaz, S. Djekhaba, C. Bendjaouahdou, Study of polyvinyl chloride/low density polyethylene wastes based blend, Int J Ind Chem, 14 (1) (2023) 1-9. https://doi.org/10.57647/j.ijic.2023.1401.02.

C. Bendjaouahdou, S. Bensaad, Properties of polypropylene/(natural rubber)/organomontmorillonite nanocomposites prepared by melt blending. J Vinyl Add Tech, 17 (2011) 48–57. https://doi.org/10.1002/vnl.20256.

C. Bendjaouahdou, S. Bensaad, Aging studies of a polypropylene and natural rubber blend, Int J Ind Chem, 9 (2018) 345-352https://doi.org/10.1007/s40090-018-0163-2.

C. Bendjaouahdou, S. Bensaad. The effects of organoclay on the morphology and balance properties of an immiscible Polypropylene/Natural Rubber blend, Energ Proced, 36 (2013) 574 – 590. https://doi.org/10.1016/j.egypro.2013.07.066.

C. Bendjaouahdou,. Ageing Study and Solvent Resistance of a Polypropylene and Organoclay Nanocomposite. Research Square.com (2022) (preprint) https://doi.org/10.21203/rs.3.rs-1930644/v1.

C. H. Chen, C. C. Teng, M. S. Tsai, F. S. Yen, Preparation and characterization of rigid poly(vinyl chloride)/MMT nanocomposites. II. XRD, morphological and mechanical characteristics. J Polym Sci Part B Polym Phys 44(15) (2006) 2145- 2154. https://doi.org/10.1002/polb.20880.

F. Gong, M. Feng, C. Zhao, S. Zhang, M. Yang, Thermal properties of polyvinyl chloride/montmorillonite Nanocomposites. Polym Deg Stab, 84 (2004) 289-294. https://doi.org/10.1016/j.polymdegradstab.2003.11.003.

W. B. Xu, Z. F. Zhou, M. L. Ge, W. P. Pan,. PolyVinyl Chloride/Montmorillonite nanocomposites. Glass transition temperature and mechanical properties. J Therm Ana Cal, 78 (2004) 91–99. https://doi.org/10.1023/B:JTAN.0000042157.96074.44.

B. Y. Zhong, H. Z. Ming, L. S. Xing, W. Z. Xue, Thermal stability, smoke emission and mechanical properties of poly(vinyl chloride)/hydrotalcite nanocomposites, Polym Degrad Stab, 93 (2008) 448-455. https://doi.org/10.1016/j.polymdegradstab.2007.11.014.

H. A. Essawy, N. A. Abd El-Wahab, M. A. Abd El-Ghaffar, PVC–laponite nanocomposites: Enhanced resistance to UV radiation, Polym Degrad Stab, 93 (2008) 1472–1478. https://doi.org/10.1016/j.polymdegradstab.2008.05.015.

M. Moghri, M. Akbarian, Effects of Nanoclay and Additives on the Fusion Characteristics and Thermal Stability of Poly(vinyl chloride) Nanocompounds,. J Vinyl Add Tech, 15 (2009) 92–98. https://doi.org/10.1002/vnl.20182.

L. Madaleno, J. S. Thomsen, J. C. Pinto, Morphology, thermal and mechanical properties of PVC/MMT nanocomposites prepared by solution blending and solution blending + melt compounding, Comp Sci Tech, 70 (2010) 804–814. https://doi.org/10.1016/j.compscitech.2010.01.016.

R. Salehiyan, S. S. Ray, J. Bandyopadhyay, V. Ojijo, The Distribution of Nanoclay Particles at the Interface and Their Influence on the Microstructure Development and Rheological Properties of Reactively Processed Biodegradable polylactide/Poly (butylene succinate) Blend Nanocomposites, Polymers, 9 (2017) 350-371. https://doi.org/10.3390/polym9080350.

B. A. Abdul Majeed, D. A. Sabar, Preparations of Organoclay Using Cationic Surfactant and Characterization of PVC/ (Bentonite and Organoclay) Composite Prepared via Melt Blending Method, Iraq J Chem Petrol Eng, 18(1) (2017) 17 – 36. https://doi.org/10.31699/IJCPE.2017.1.2.

A. L. G. Saad, H.A. Aziz, O. I. H. Dimitry, Studies of Electrical and Mechanical Properties of Poly (vinyl chloride) Mixed with Some Electrically Conductive Additives. J Appl Polym Sci, 91 (2003) 1590-1598. https://doi.org/10.1002/app.13239.

M. A. Soto-Oviedoa, O. A. Arujoa, R. Faiez, C. Mirabel, M. Z. Rezende, M. A. De Paoli, Antistatic coating and electromagnetic shielding properties of a hybrid material based on polyaniline/organoclay nanocomposite and EPDM rubber, Synt Mat, 156 (2006) 1249–1255. https://doi.org/10.1016/j.synthmet.2006.09.003.

E. M. Sadek, S. L. Abd-El-Messieh, A. A. Khalil, N. A. Fatthallah, A. I. A Eid, K. M. El-Ashry, A.M. Motawie, Some Studies on Poly (vinyl chloride)/Layered Silicate Nanocomposites: Electrical, Antibacterial and Oxygen Barrier Properties, IOSR J App Chem, 7(11) (2014) 37-45. https://doi.org/10.9790/5736-071114648.

R. S. Chen, S. Ahmad, S. Gan, Characterization of recycled thermoplastics-based nanocomposites: Polymer-clay compatibility, blending procedure, processing condition, and clay content effects, Comp Part B: Eng, 131(15) (2017) 91-99. https://doi.org/1016/j.compositesb.2017.07.057.

C. L. De Dicastillo, E. Velásquez, A. Rojas, A. Guarda, M. J. Galotto, The use of nanoadditives within recycled polymers for food packaging : Properties, recyclability, and safety, Comp Rev Food Sci Food Saf, 19 (2020) 1760–1776. https://doi.org/10.1111/1541-4337.12575.

Y. Turhan, M. Dogan, M. Alkan,. Poly (vinyl chloride)/Kaolinite Nanocomposites: Characterization and Thermal and Optical Properties. Ind Eng Chem Res, 49 (2010) 1503–1513. https://doi.org/10.1021/ie901384x.

C. Bendjaouahdou, K. Aidaoui, Synthesis and characterization of polyvinyl chloride/wood flour/organoclay ternary composites, Polym Polym Comp, 29 (2021) 949-958. https://doi.org/10.1177/09673911211031139.

E. M. Sadak, D. El-Komy, A.M. Motawie, M. S. Darwish, S. M. Ahmed, S. M. Mokhtar, PVC-clay nanocomposites: Preparation, mechanical and thermal properties, J Sci Res Sci, 36(1) (2019) 453-468. https://doi.org/10.21608/jsrs.2019.58526.

A. E. Fetouh, et al., Improving the mechanical and thermal properties of chlorinated poly vinyl chloride by incorporating modified CaCO3 nanoparticles as a filler, Turk j Chem, 43(3) (2019) 750-759. https://doi.org/10.3906/kim-1808-51.

A. L. Jembere, M. B. Genet, B. Sintayehu, Evaluation of precipitated CaCO3 produced from locally available limestone as a reinforcement filler for PVC pipe, Sic Rep, 14: (2024) 11234. https://doi.org/10.1038/s41598-024-58594-7.

H. Ismail, Y. Manusamy, Polyvinyl Chloride/Organoclay Nanocomposites: Effects of Filler Loading and Maleic Anhydride, J Reinf Plast Comp, 26(16) (2007) 1681-1694. https://doi.org/10.1177/0731684407081446.

H. Ismail, I. Surya, The silica filled natural rubber in presence of epoxidized natural rubbers: curing, swelling and tensile properties. J Physic: Conf Ser, 1501 (2020) 012024. https://doi.org/10.1088/1742-6596/1501/1/012024.

L. Bokobza, The Reinforcement of Elastomeric Networks by Fillers, Macromol Mater Eng, 289 (2004) 607–621. https://doi.org/10.1002/mame.200400034.

H. Deng, F. Qiang,. Recent progress on the confinement, assembly, and relaxation of inorganic functional fillers in polymer matrix during processing. Macrom Rapid Com, 38 (2017) 1-14. https://doi.org/10.1002/marc.201700444.

S. Garoushi, P. K. Vallittu, J. L. V. Lassila, Short glass fiber reinforced restorative composite resin with semi-inter penetrating polymer network matrix, Dent Mat, 23 (2007) 1356-1362. https://doi.org/10.1016/j.dental.2006.11.017.

C.Y. Wan, X.Y. Qiao, Y. Zhang, Y. X. Zhang, Effect of Different Clay Treatment on Morphology and Mechanical Properties of PVC-Clay Nanocomposites, Polym Test, 22(4) (2003) 453-461. https://doi.org/10.1016/S0142-9418(02)00126-5.

G. E. Mingglian, G. Demin, Influence of Organoclay Prepared by Solid State Method on the Morphology and Properties of Polyvinyl Chloride/Organoclay Nanocomposites. J Elast Plast, 40(3) (2008) 223-235. https://doi.org/10.1177/0095244307084905.

W. B. Xu, Z. F. Zhou, M. L. Ge, W. P. Pan, Polyvinyl chloride/Montmorillonite nanocomposites: Glass transition temperature and mechanical properties, J Therm Analy Calorim, 78 (2004) 91–99. https://doi.org/10.1023/B:JTAN.0000042157.96074.44.

Published

Issue

Section

License

Copyright (c) 2025 Journal of Applied Engineering Sciences & Technology

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.